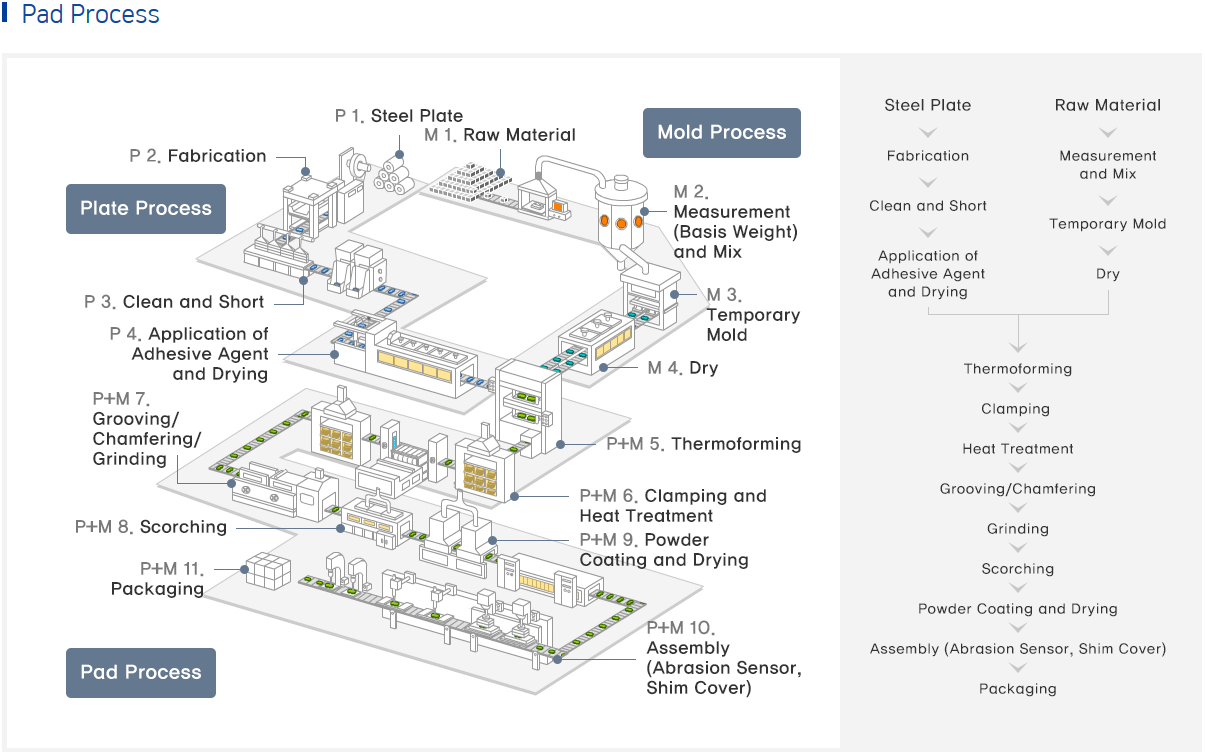

Plate Process

Plate 01.

Steel Plate

start

Plate 02.

Fabrication

View

Plate 02

Fabrication

Attaching metallic molds or tools to the press to cut or create a shape by pressurizing.

Plate 03.

Clean and Short

View

Plate 03

Clean and Short

Removing grease, rust, and burr from the surface and widening the surface area to improve the adhesion before applying the adhesive agent on a back plate.

Plate 04.

Application of Adhesive Agent and Drying

View

Plate 04

Application of Adhesive Agent and Drying

Applying a liquid adhesive agent to the adhesive zone of the mold and the back plate for easier adhesion, as well as drying on the conveyor-type hot-air drying furnace.

Mold Process

mold 01.

Raw

start

mold 02.

Measurement and Mix

View

mold 02

Measurement and Mix

Measurement(basis weight)

Accurately measuring raw ingredients required for each material specification.

Mix

Evenly distributing each accurately measured raw ingredient, and proceeding with correcting the tangled fibroid materials.

Accurately measuring raw ingredients required for each material specification.

Mix

Evenly distributing each accurately measured raw ingredient, and proceeding with correcting the tangled fibroid materials.

mold 03.

Temporary Mold

View

mold 03

Temporary Mold

Creating a mock-up with the same shape as the permanent mold to make molding easier.

mold 04.

Dry

View

mold 04.

Dry

Proceeding with drying the temporary mold using hot air or a heater in order to reduce inflation, cracks, and other property deviations due to moisture in thermoforming.

Pad Process

P+M 05.

Thermoforming

View

P+M 05

Thermoforming

Proceeding with mixed materials for a temporary mold or directly inputting to form a product at an appropriate temperature, pressure and time.

P+M 06.

Clamping and Heat Treatment

View

P+M 06

Clamping and Heat Treatment

Clamping

Pressurizing the product prior to heat treatment—as a supporting process—in order to maintain the physical property and prevent the deformation of the product caused by the heat treatment.

Heat treatment

Applying heat of a certain temperature and time to the product in order to melt the bonding material, thus increasing the cohesiveness between raw materials and allowing them to harden them to stabilize the physical property.

Pressurizing the product prior to heat treatment—as a supporting process—in order to maintain the physical property and prevent the deformation of the product caused by the heat treatment.

Heat treatment

Applying heat of a certain temperature and time to the product in order to melt the bonding material, thus increasing the cohesiveness between raw materials and allowing them to harden them to stabilize the physical property.

P+M 07.

Grooving / Chamfering / Grinding

View

P+M 07

Grooving / Chamfering / Grinding

Grooving

Making grooves to the mold after the heat treatment to improve the discharge of airborne dust and noise.

Chamfering

Fabricating both ends of the mold to improve the disc contact and noise characteristic.

Grinding

Polishing the product to the specified thickness to ensure the degree of parallelization and flatness.

Making grooves to the mold after the heat treatment to improve the discharge of airborne dust and noise.

Chamfering

Fabricating both ends of the mold to improve the disc contact and noise characteristic.

Grinding

Polishing the product to the specified thickness to ensure the degree of parallelization and flatness.

P+M 08.

Scorching

View

P+M 08

Scorching

Burning organic matters on the surface of pad friction materials a high temperature for a certain period of time to improve the initial effect and brake fade.

P+M 09.

Powder Coating and Drying

View

P+M 09

Powder Coating and Drying

Spraying the powder coating paint on the product and coating the surface for a certain time and temperature to improve corrosion resistance.

P+M 10.

Assembly (Abrasion Sensor, Shim Cover)

View

P+M 10

Assembly (Abrasion Sensor, Shim Cover)

Assembling a shim and a cover shim to prevent noise and damage to the

pad, and assembling an abrasion sensor, which indicates the abrasion

status by making a beep sound to alert when replacement is due.

P+M 11.

packaging

Finish

苏公网安备32021402002688

苏公网安备32021402002688