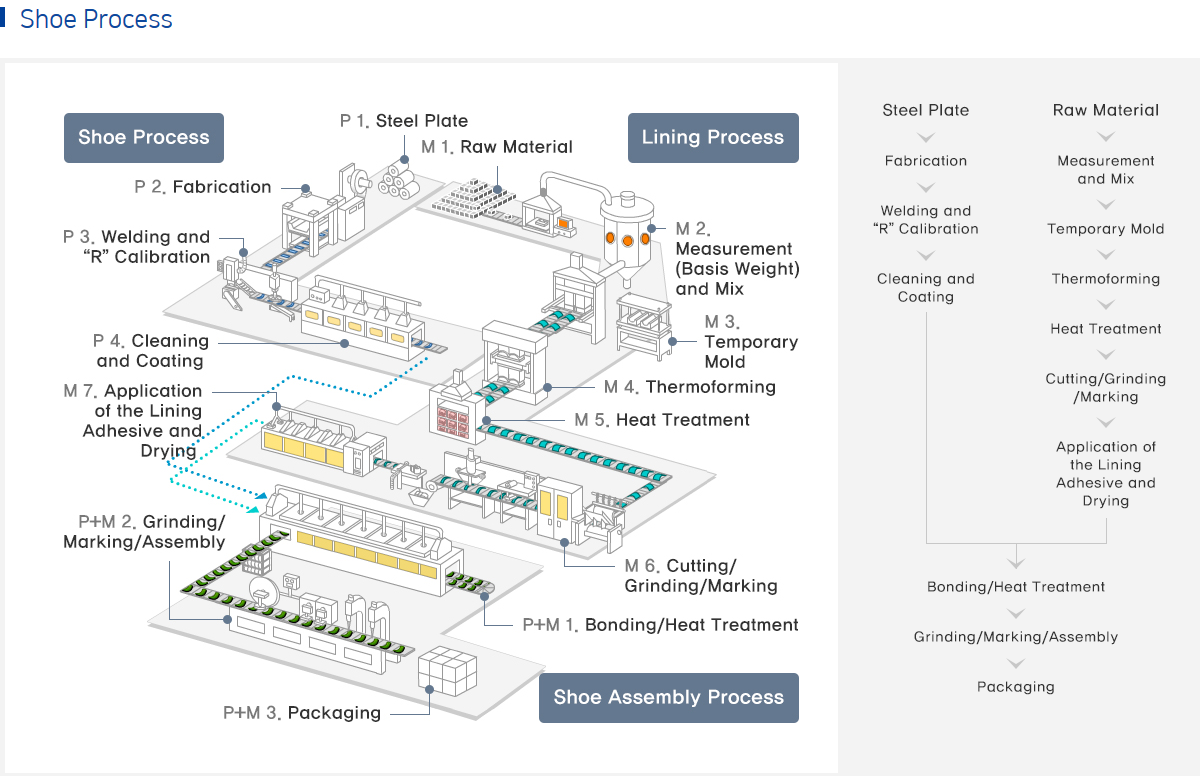

Shoe Process

Plate 01.

Steel Plate

start

Plate 02.

Fabrication

View

Plate 02

Fabrication

Attaching metallic molds or tools to the press to cut or create a shape by pressurizing.

Plate 03.

Welding and “R” Calibration

View

Plate 03

Welding and “R” Calibration

Proceeding with resistance welding to the web and the rim which are components of the shoe, and calibrating the R value of the deformed shoe during the welding process, appropriate to the drawing.

Plate 04.

Cleaning and Coating

View

Plate 04

Cleaning and Coating

Cleaning working fluids and foreign matters of the shoe and applying the coating fluid to prevent corrosion and improve the adhesion of the lining and the shoe.

Lining Process

mold 01.

Raw Material

start

mold 02.

Measurement and Mix

View

mold 02

Measurement and Mix

Measurement(basis weight)

Accurately measuring raw ingredients required for each material specification.

Mix

Evenly distributing each accurately measured raw ingredient, and proceeding with correcting the tangled fibroid materials.

Accurately measuring raw ingredients required for each material specification.

Mix

Evenly distributing each accurately measured raw ingredient, and proceeding with correcting the tangled fibroid materials.

mold 03.

Temporary Mold

View

mold 03

Temporary Mold

Creating a mock-up with the same shape as the permanent mold to make molding easier.

mold 04.

Thermoforming

View

mold 04

Thermoforming

Proceeding with mixed materials for a temporary mold or direct input to form a product at an appropriate temperature, pressure and time.

mold 05.

Heat Treatment

View

mold 05

Heat Treatment

Applying heat to the product of a certain temperature and time to melt the bonding material in order to increase the cohesiveness between raw materials, as well as to harden them for the stabilization of the physical property.

mold 06.

Cutting / Grinding / Marking

View

mold 06

Cutting / Grinding / Marking

Cutting

Cutting the sheet lining after the heat treatment is completed to the specified width, according to the drawing.

Grinding

Polishing the inside/outside of the lining deformed by heat to make the application of adhesion easier.

Marking

Issuing a “Lot Number” to identify the production history of the product.

Cutting the sheet lining after the heat treatment is completed to the specified width, according to the drawing.

Grinding

Polishing the inside/outside of the lining deformed by heat to make the application of adhesion easier.

Marking

Issuing a “Lot Number” to identify the production history of the product.

mold 07.

Application of the Lining Adhesive and Drying

View

mold 07

Application of the Lining Adhesive and Drying

Applying the adhesive agent evenly to the lining surface to bond the lining to the shoe and proceed with drying.

Shoe Assembly Process

P+M 01.

Bonding / Heat Treatment

View

P+M 01

Bonding / Heat Treatment

Pressurizing with a consistent pressure for a given time and temperature to bond the shoe and lining.

P+M 02.

Grinding / Marking / Assembly

View

P+M 02

Grinding / Marking / Assembly

Grinding

After bonding the lining and the shoe, proceeding with polishing the lining surface to the value specified on the drawing.

Marking

Issuing a lot number to identify the production history of the product.

Assembly

Assembling a parking lever, a pin, etc.

After bonding the lining and the shoe, proceeding with polishing the lining surface to the value specified on the drawing.

Marking

Issuing a lot number to identify the production history of the product.

Assembly

Assembling a parking lever, a pin, etc.

P+M 3.

Packaging

Finish

苏公网安备32021402002688

苏公网安备32021402002688